Case studies

Design and Manufacture of EVTOL airframes to specification and time

Engaged by a leading company in the US to build 3 prototype planes (as a result of a competitive tender process) we ended up building 19. Our team successfully delivered a full airframe build - including pilot seat, pylons, and internal structures - on time, on spec, and in support of an ambitious next-generation programme. Our agility, openness, and accuracy in the design and build process lead to repeat business with a global leader in the aerospace world.

“Advanced Aerospace has been a true pleasure to partner with as our program grew from an idea into a product. They continuously and proactively communicated and would immediately raise concern if there was an issue or a decision that had to be made, often with sound engineering solutions already prepared for those conversations. AAL is not just a vendor, but a partner to their customers and has been critical to our success in meeting our program goals."

Director of Manufacturing, Kitty Hawk

Serving Air New Zealand and Virgin Atlantic

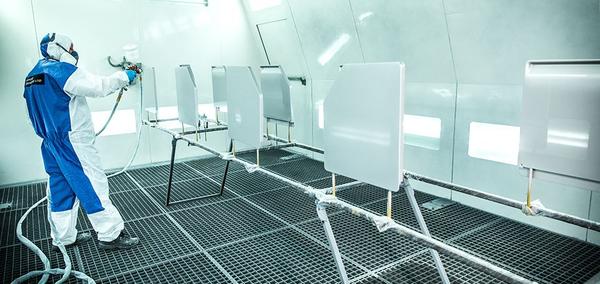

When the maker of Air New Zealand’s business class seat were suddenly left without a tray table manufacturer in 2009, they trusted Advanced Aerospace to produce this vital and complex part within a short time frame.

The challenges included creating a set of manufacturing drawings, machining four sets of composite tooling, jigs and fixtures, as well as setting up dedicated work spaces for secondary bonding and post-paint assembly. We also had to master applying a water-based three-stage colour that Air New Zealand had chosen. Added to this, we produced a complete set of tray table process paperwork, including manufacturing instructions and compliance documents.

Air New Zealand were so pleased with the outcome that in 2012 they invited Advanced Aerospace to create their next generation tray - a tray which Virgin Atlantic also bought the rights to.

In 2014, Air New Zealand also commissioned us to refurbish all their 737 monuments - a complex task which involved stripping all coatings, repairing damage, repainting and reassembling.

“The partnership between Advance Aerospace and Air New Zealand has been very successful and instrumental to the success of critical Air New Zealand projects.”

Air New Zealand

Delivering innovative carbon fibre solutions

Advanced Aerospace also has a reputation for working at the cutting edge of carbon fibre aeronautical design. One project we were proud to be involved with was making the wings and fuselage for an experimental aircraft designed for use on helicopter pads.

This exciting project is another example of Advanced Aerospace’s ability to produce large carbon fibre structures - in this case the wings and fuselage. We achieved this by using carbon fibre prepreg with Nomex Honeycomb and PU foam cores, followed by a vacuum bag oven cure

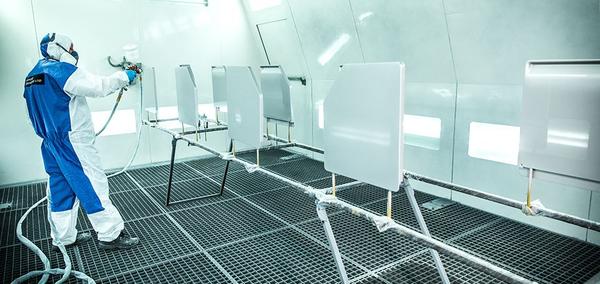

Material and Process testing

Advanced Aerospace has built an onsite lab to conduct M&P testing requested of our aerospace customers.

Prototyping involves a lot of experimentation, with materials and adhesives (as examples) and involved the design and manufacture of jigs and fittings to measure consistency and accuracy.

This is a critical service we offer to enable our customers to make good, informed decisions.