Materials

Every C-Quip product begins with a commitment to using the highest quality materials available. Our selection process is driven by performance, durability, and precision. Every component we produce meets the same uncompromising standard, regardless of application or environment.

Pre-preg carbon fibre

We manufacture with the highest grade of pre-preg carbon fibre. Controlled resin content and fibre alignment deliver high fibre-volume fractions and low void content, resulting in lighter parts with superior stiffness and fatigue performance. Autoclave curing locks in repeatable quality, project after project.

Titanium

At C-Quip, titanium is the preferred specification for metallic hardware and load-bearing elements. Its outstanding strength-to-weight ratio and complete resistance to corrosion make it the benchmark for marine, aerospace, and motorsport applications. Components manufactured in titanium maintain their integrity over decades, even in the harshest environments.

316 stainless steel

While titanium is our benchmark, we currently manufacture many fittings and interfaces in 316 stainless steel. Its superior corrosion resistance makes it a robust option for marine use. When specified, we engineer each stainless component with the same care, finishing, and isolation measures as titanium, ensuring compatibility with carbon fibre structures and long service life.

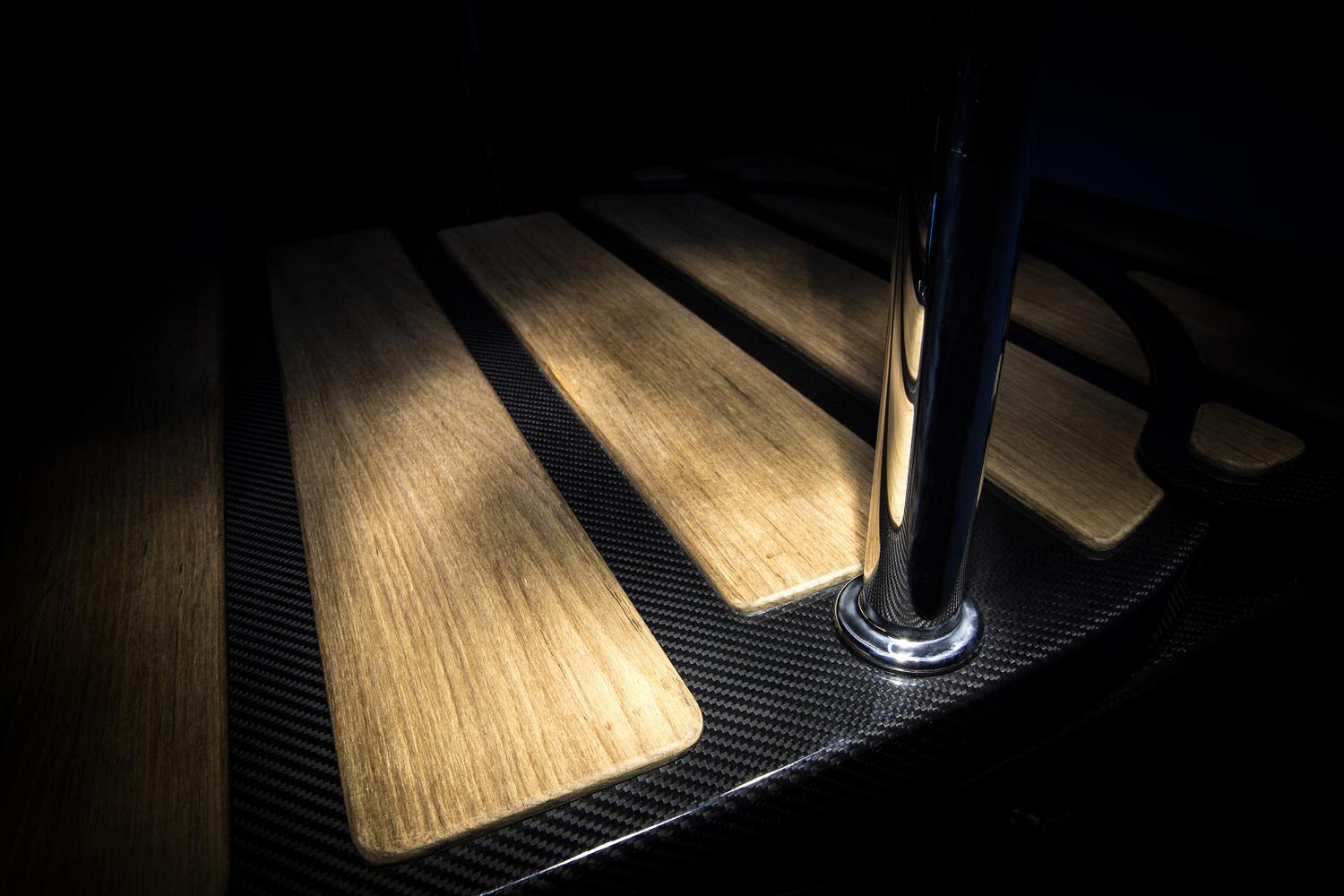

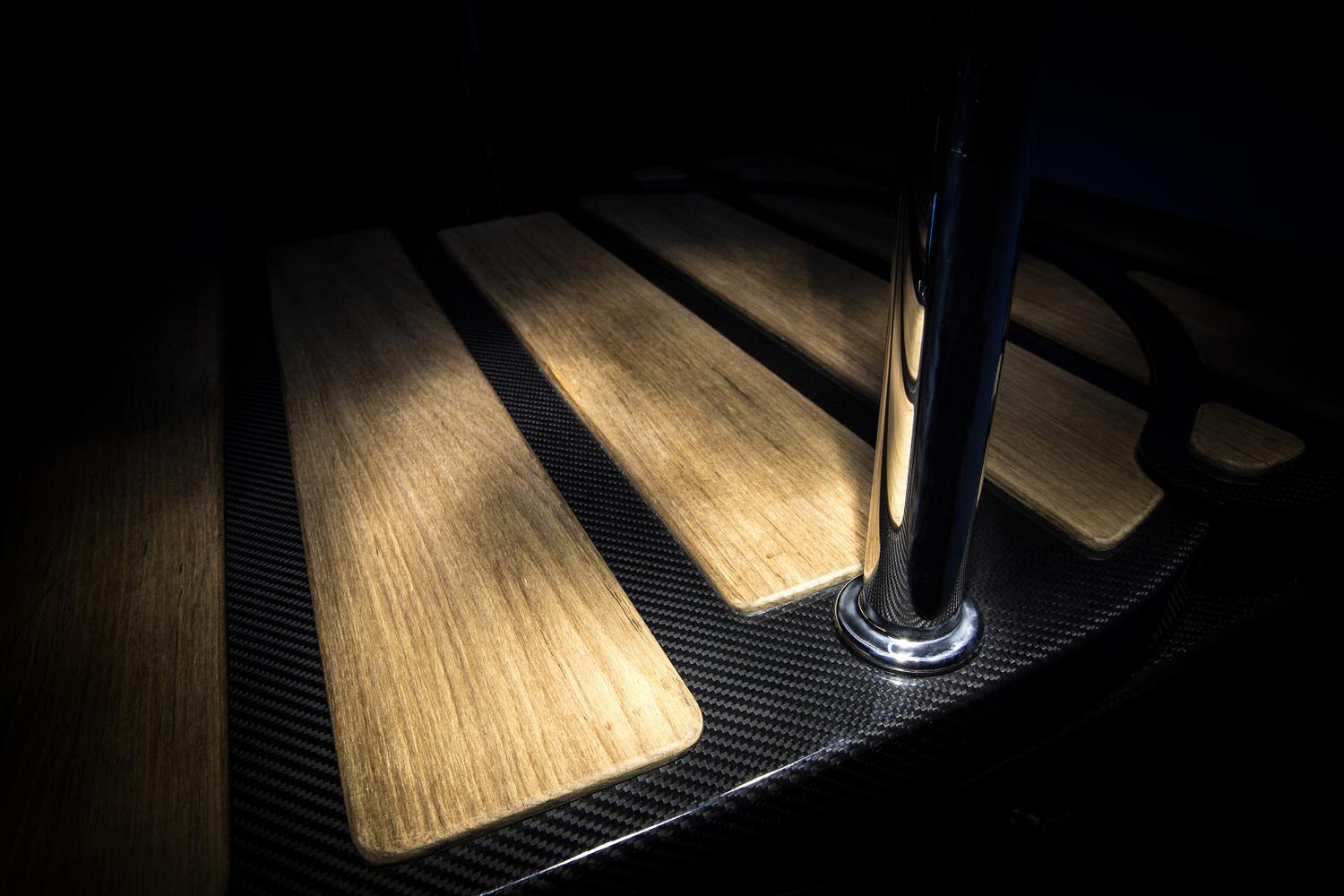

Sustainably sourced teak

For touch points such as steps and handrails, we use responsibly sourced teak for its stability when wet, and long service life. We match finishes to the vessel’s specification and adhere to the highest marine standards.

Facilities

Our two facilities specialize in the design and manufacture of the finest carbon fibre equipment. Each site is equipped with advanced tooling, autoclave, and clean room capabilities. Backed up by expert technicians at both sites, these aren’t just manufacturing facilities - they’re the engines of our innovation.

Auckland,

New Zealand

Autoclave Clean ROOM Prototype tooling Paint room 3D modeling Finite element analysis

Our Auckland facility has been in operation for over 20 years, and has been the site of countless builds across marine and aerospace sectors. Home to a talented group of composite engineers and production specialists, this facility is where ideas are brought to life and performance is built into every layer. Going forward, the introduction of our Philippines facility means that our Auckland site will be focusing more on custom and technical builds - allowing faster prototyping and greater flexibility for our most complex projects.

Clark,

Philippines

Autoclave Clean room Prototype tooling Paint room

Our PHP facility in the Philippines is where we will carry out the builds of our standard products. Produced with the same C-Quip quality and attention to detail, this facility has been purpose-built for efficiency and high quality production. Working closely with our Auckland team, the Clark site ensures consistency across every component, while enabling greater production capacity for both current and future demands across marine, aerospace, and motorsport.