Marine

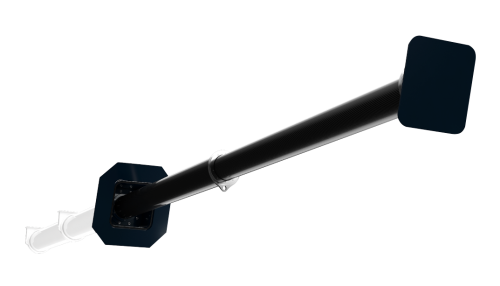

Elegant, innovative & luxurious marine equipment

C‑Quip are specialist designers and manufacturers of the world’s finest superyacht equipment.

Products

Explore our range

Kiwi innovation and ingenuity delivering world-class superyacht equipment

Our capabilities

We craft carbon fibre to perfection

To create our products, carbon fibre is carefully layered into moulds and then pressure baked in an autoclave oven. After trimming and painting, final assembly takes place which includes fitting metallic components as well installing hydraulic and electrical systems where required.

Impeccably designed to ensure the best results

When you enquire about customising a C‑Quip product, we take great care during the initial design phase. First we discuss your requirements and then our inhouse design team will produce concept drawings. When these are signed off, 3D modelling and finite element analysis help to ensure your precise design is manufactured.

Expertly manufactured then rigorously tested

Our clients include shipyards and naval architects, as well as representatives and crew of the world’s largest yachts. Our experience means we are able to manage projects of all sizes, to the very highest specifications and quality. Once built, our in-house technicians test components to rigorous C‑Quip standards before delivery.

Installation with added peace of mind

During the installation stages, we will provide you with comprehensive technical support to ensure perfect installation of your new C‑Quip products. C‑Quip’s strict code of business practices and warranties also give you the added assurance of the quality of materials used as well as their long-term reliability.

Premium materials

We use the highest quality materials available on the market. Titanium, stainless steel, teak, and the finest pre-preg carbon fibre all mesh together in a bridge between art and science. Our approach leaves no stone unturned, and we pride ourselves in using finest materials to create our superyacht jewellery.

Our design, manufacture and fit-out process

Your enquiry

Understanding what C‑Quip can do for you

Our designers will work with you to understand the scope of work and equipment required, and then produce concepts for how C‑Quip products will integrate with your vessel.

Design

Detailed concepts are created for initial approval by the client.

After an order is placed, our team then prepares drawings and models for your final sign off. Once approved, these are released to manufacturing for final production.

Manufacturing

Multi-stage carbon fibre production begins.

Our technicians produce and test your new products following strict quality control guidelines in accordance with the ISO9001 quality standard.

Testing

Ensuring your new C‑Quip products are perfect.

After final assembly, each piece of your equipment is rigorously tested until it passes C‑Quip’s quality control as well as industry and customer certification standards.

Delivery

Global delivery with C‑Quip installation support.

We carefully pack and ship the new equipment direct to you, and where required, a C‑Quip technician will come to you for installation.

Testimonials

Innovative products and impeccable service delivered to the world’s finest superyachts